Manufacturer of printed tapes

The production process at TCM Service respects environmental standards. Only the best raw materials are used in production, guaranteeing high quality and customer satisfaction. The tapes offered by TCM Service maintain their properties in terms of durability, regardless of how much time passes. We offer custom printed tapes on various types of media, with the strong adhesive of the customer’s choice (Hot Melt, Solvent, or acrylic). This tape is a reliable way to protect your shipments from damage. We base our operations on long-term relationships with customers and on carefully managed products. TCM Service is constantly expanding its product range so that every customer finds the option that is right for them.

Flexographic printing

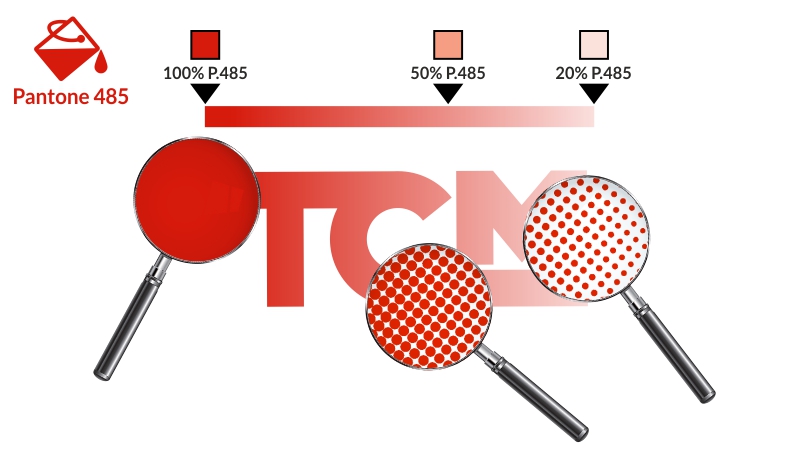

TCM Service offers flexographic printing. This type of printing is very versatile. In most situations, this is a company logo, an advertising slogan, an address details, or a warning message. TCM Service offers printing on PVC, paper, and polypropylene tapes. The ‘sandwich’ method is a great solution. With this method, the printing is done before the adhesive is applied. This ensures that the printing will be resistant to weather conditions and mechanical damage. In addition, prints made using this method are distinguished by their intense colours. Printing can be done in any three colours from the Pantone C and HKS palettes, and sometimes also the RAL colour palette.

Guidelines for preparing prints on adhesive tapes

As a tape manufacturer, TCM Service attaches great importance to the technical specifications of its products, and the quality and precision of the printing. Employees make every effort to ensure that printed tapes are produced to the highest standards and to the specifications of the order. The printing designs for the tape should be prepared according to the requirements (in vector form). All projects that do not meet these requirements (such as images with a pixel structure) must be converted. Without these guidelines both in the logo and in the other graphic elements, the printing die will not be properly prepared and the tape will not be printed. Order processing is much more efficient with files in the correct format.

Providing information for printing on tapes

Tapes are printed using the flexographic printing method. Printing is not possible with pixel-based images, so the data to be printed on the tape should be in vector format. To avoid conflicts between different systems (Windows and Mac), it is worth converting the file to PDF. Importantly, simply saving or exporting to PDF does not solve the issue – paths and fonts must be converted to curves.

Raster

A raster is a monotone image composed of tiny dots, giving the impression of halftones when viewed from a normal distance. Printing is based on the Pantone C and HKS colour palette, though RAL colours can also be used. Raster allows us to obtain several shades from one colour, while keeping a minimum of 20% and a maximum of 80% of the original Pantone or HKS colour.

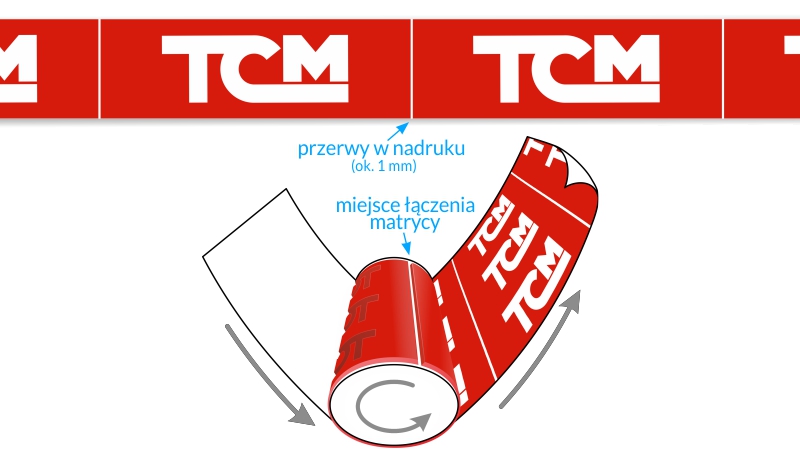

Die length

The length of the dies determines the area that can be used for printing logos and other information as well as the free space between them. TCM Service has dies in lengths of 150.7 mm 188.5 mm, 219.8 mm, 245.0 mm, 251.2 mm, 282.6 mm, 314.0 mm, 345.4 mm, 370.5 mm and 395.6 mm. Printing is done by sticking a die onto a roller, where each rotation of the roller is one repetition of the design on the tape.

Print on the entire surface of the tape

If the customer wants the whole surface of the tape to be printed and the background is darker than the elements on it, a line will be visible on the tape where the dies are joined (1-2 mm). The distance between the lines depends on the length of the die. A special Sleeve die, which only comes in a length of 314.0 mm, can be used such that the lines are not visible.

Edge printing

The base material on which the print is made is usually 144 or 150 mm wide. Most often 3 repetitions are performed with one rotation of the roller. During the printing process or when cutting with a knife, small offsets (1-2 mm) are possible, which are usually not noticeable with a correctly executed pattern.

PVC tapes

These are high-quality adhesive tapes that provide an excellent base for printing. They are used for various types of packaging and are very popular among buyers. PVC tapes use an adhesive based on natural rubber. Its main advantage is that it sticks to almost any surface immediately upon application. PVC tapes have another practical feature – they unwind quietly and do not stretch. They are available in various roll widths and colours. They are distinguished by their high level of insulation and flexibility, which makes them ideal for use on uneven surfaces. They are often chosen by customers because they are highly resistant to abrasion and harsh weather conditions.

Paper tapes

Paper tapes are popular adhesive media with high strength. This type of product offers the same adhesive properties as PVC tape. The adhesive used in paper tapes, which is produced on the basis of natural rubber, is responsible for strong adhesion. Like PVC, paper tapes are distinguished by their silent unwinding. They are able to effectively secure the contents of packages. Thanks to their easy recycling, they are environmentally friendly products and are therefore increasingly chosen by shipping and removals companies. Unfortunately, paper-based adhesive media are not as versatile a surface for printing as PVC tapes. Raster layers do not come out as well as they do on PVC.

Polypropylene tapes

Polypropylene tapes are divided into several types. They are classified according to the type of adhesive used.

Acrylic polypropylene tapes

They are probably the most popular type of adhesive tape available on the market. These tapes use a water-based adhesive that works well on smooth surfaces such as film or paper. The adhesion of acrylic tapes increases over time. They are recommended for sealing lightweight boxes. They should be used in temperatures above freezing and in an environment without excessive moisture.

Hot Melt polypropylene Tapes

These products are based on synthetic rubber adhesive. Hot Melt polypropylene tapes are stronger than acrylic tapes, but inferior in adhesion to natural rubber-based adhesive tapes. They provide the greatest adhesive strength immediately after application. They are recommended for sealing medium sized boxes. Very often, Hot Melt propylene tapes are applied using hand-held dispensers. They make noise when unwinding, which can have an adverse effect on working comfort. They are relatively resistant to moisture, but should be used in temperatures above freezing.

Solvent polypropylene tapes

These tapes are distinguished by the fact that they use a natural rubber-based adhesive with high initial adhesive strength. They are most often used to seal packages and pallets of large size. This is the most expensive option to buy when it comes to packing tape, but it stands out as the best value for money. Solvent polypropylene tapes perform well on both smooth and porous surfaces. They exhibit high resistance to moisture and a wide range of temperatures, so they are used in various fields of industry. All types of Solvent polypropylene tapes are printable.

Printed tapes offered by TCM Service

TCM Service’s extensive range of adhesive tapes includes PVC, paper, and polypropylene tapes. The PVC tapes in the brand’s range are available as products with a total thickness of 53 µm (backing and adhesive). They are available in white, brown, and clear colours. TCM Service offers this type of tape exclusively with printing. The paper tapes on offer are available in brown and white. Their total thickness is 120 µm. This type of adhesive tape is sold by TCM Service exclusively in printed form. As far as polypropylene tapes are concerned, TCM Service offers products with Hot Melt and Solvent acrylic adhesive. The acrylic tapes are produced entirely in-house, ensuring that they meet the customer’s needs 100%. The company matches the product in terms of film thickness and amount of adhesive to its intended use. Acrylic polypropylene tapes are available in two versions – silent and loud unwinding. TCM Service prints on acrylic tapes using the so-called ‘sandwich’ method – the printing is located under the adhesive layer. This ensures that the pattern is resistant to abrasion on the outer layer of the tape. The Hot Melt tapes in TCM Service’s range are available in several film thicknesses and adhesive options (Hot Melt, Super Hot Melt, and Extra Hot Melt). Hot Melt adhesive products offer high adhesion. The Solvent polypropylene tapes sold by TCM Service come in a total thickness of 42 µm. Three colours of these products are available to customers – white, brown, and clear.

Brand promotion

Adhesive tapes are widely used by many businesses. They are used to seal packages and documents for shipping. If a package presents a company’s logo and information to the world, it also underlines that company’s professionalism. Building a relationship with the customer starts when opening the package. Packaging can become so unique that it sets a company apart from others in its industry. Consumer confidence in a company that takes care of its image is undoubtedly increased. Moreover, it is more easily remembered. One of the basic activities of a company’s marketing strategy is the dissemination of its logo on all kinds of promotional materials. Such forms of promotion include printed packing tapes, which, when used to seal packages, advertise the company’s activities. Extensive marketing activities build a positive image of the company, which certainly translates into its profits. The company’s position advantage over the competition becomes established and its brand recognition increases.

Security and easy identification of the package

The primary function of packing tapes is to protect the boxes sealed with them. This prevents the package from being damaged or unintentionally opened, and also protects it from external factors – moisture, temperature changes and dust. A properly secured package is sure to reach its recipient intact. It is worth bearing in mind that a package sealed with printed tape is not difficult to identify. This then greatly facilitates the work of those who prepare packages in warehouses and of those responsible for their safe delivery. The chances of losing a branded package are slim. The printing on packing tapes is visible from a distance and catches the eye with a simple message. The number of places a package will find itself on its journey and the number of people who will interact with it ensure that the brand is remembered.

First impressions count

The consumer who orders products on the Internet is often the first to come into contact with specific brands. Packing tape with the company logo ensures that the customer immediately knows where the package came from. That customer will then remember the logo of the company using such packing tape. At the same time, it demonstrates the seller’s professional approach to the consumer. A package with a brand logo and personalised slogan is aesthetically pleasing and, thanks to the visual effect achieved, increases customer confidence in the company. The use of printed tape when shipping products creates a good first impression. In addition, the company gains a reputation for caring for customer comfort and convenience.

Tailor-made tapes

Printed tapes are great for securing packages, tailored do Customers’ needs, while also serving as a discreet promotional tool. When a brand is just building its market recognition, using printed tapes is a practical marketing measure. In the age of online shopping and rapid growth of the e-commerce industry, consumers often order products from several brands at the same time. It is crucial that the package stand out from the rest. A striking packing tape will stay in the recipient’s memory for longer. Printed tapes also allow you to present useful information about your company. In addition to the logo and address, they can have a slogan directed to the customer. When choosing the type of printing on the tape, it is worth taking into account all the benefits that can be achieved through such action. In addition, it is a good idea to use such tape in other places where it works well.

Printed packing tapes – where can I buy them?

There is no shortage of companies selling customised printed tape, but it is best to order these products from experienced suppliers. When looking for a suitable retailer, you can check the offers on the Internet or find a company locally. Due to the fact that, apart from the print, the choice of other specifications of the tape is crucial, it is worth considering not only price, but also the size of the roll and the type of adhesive used. As an experienced manufacturer of printed tapes, TCM Service not only has the knowledge and experience, but also the appropriate technological background. As a result, it offers the highest quality printed tapes to promote companies. Prints on products are made using the flexographic method, which guarantees perfect reproduction of details and precision printing. In addition, this type of printing is distinguished by its high resistance to abrasion. In order to meet our customers’ expectations, TCM Service offers its range at very favourable prices, with printed tapes available in quantities as small as one box.