History of TCM

The origins of TCM Service date back to April 1991, when the company was founded under the name M Service. Employing only three people, the company specialised in selling products made by the well-known American company 3M. Just one year later, M Service was transformed into a limited liability company. December 1992 brought important investments, with the company purchasing its first printing machine. Just twelve months later, another was added. The next two years saw the dynamic development of the M Service brand, resulting in further investments. In July 1995, M Service purchased the machine needed for winding tape.

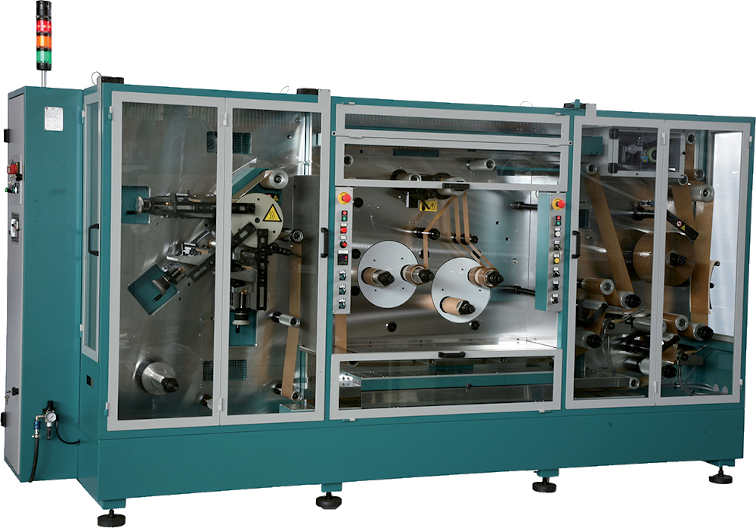

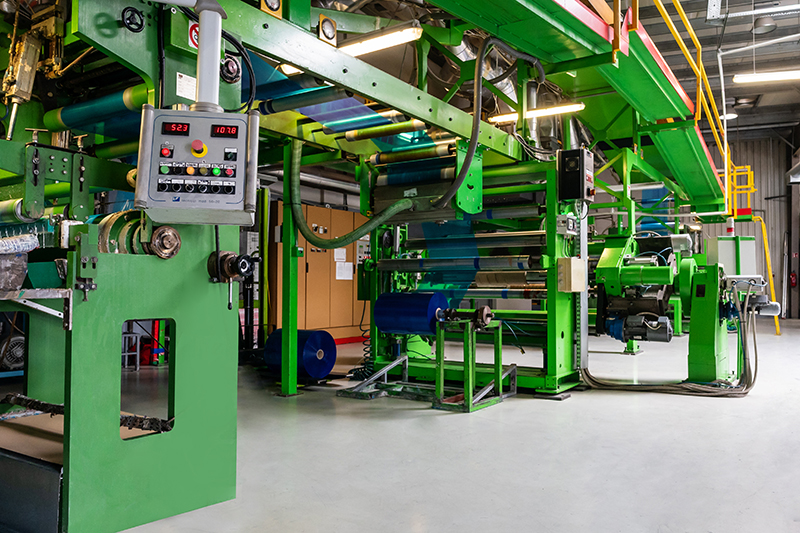

Two months later was a milestone in the company’s history – the company changed its name from M Service to TCM Service. The company and its production continued to grow, and in March 1996 the TCM Service machine park added a third printing machine. The year 1997 brought more projects. TCM Service expanded its production resources with a die-cutting and labelling machine. Three years later, in May 2000, the production plant was expanded with the purchase of a coating and printing machine. Further growth of the company necessitated new acquisitions: In June 2001, the company purchased a Kampf tape winding machine. A month later, TCM Service’s efforts to implement a Quality Management System were successfully concluded and the brand was awarded ISO 9001:2000 certification.

The systematic expansion of the machine park, as well as growing customer demand, prompted the owners of TCM Service to form a relationship with 3M Europe in the area of technical tape packaging, which took place in May 2002. One month later, an automatic log slitter was added to the company’s production line for the packaging of technical tapes. Three years later, TCM Service was also equipped with a G&A machine, which is also used for winding tape.

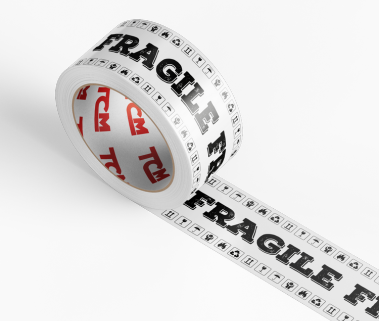

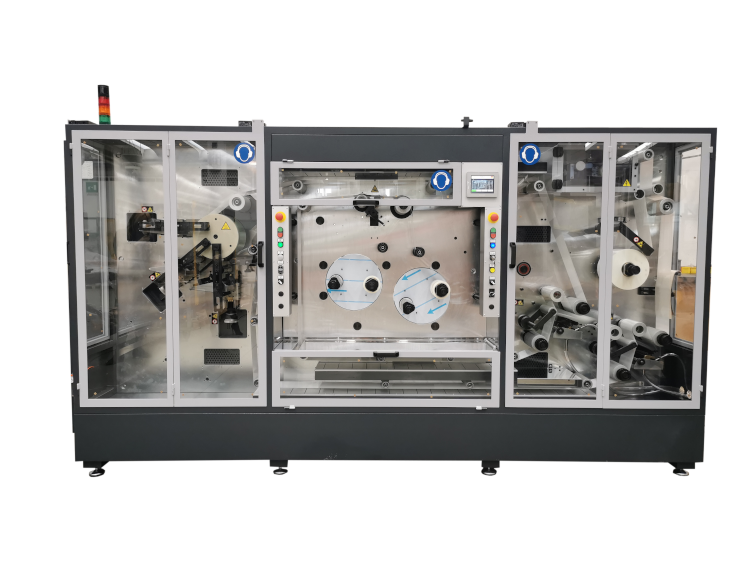

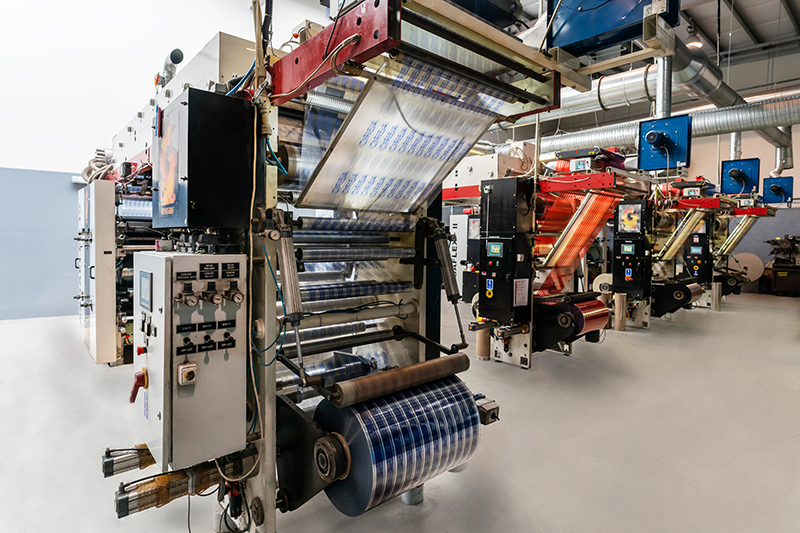

In January 2008, TCM Service implemented the ISO 14001:2004 Environmental Management System, the main objective of which is to support environmental protection and prevent environmental pollution. To this end, the company has minimised the use of solvents in the production of tapes and introduced ECOSOLVENT tapes to its range. Annual investments in environmental protection also help the company ensure that its production processes do not have a negative impact on workers’ health. A month later, an innovative line for the production of adhesive tapes with printing on the underside was launched. In 2012, TCM Service merged with SABA, a manufacturer of adhesive tapes, forming a single capital group. Equipped with machines from SIAT (the world’s largest manufacturer of wrapping, box folding, and sealing machines), the TCM service brand focused its activities on expanding the production of flexographic printed tapes.

By 2017, TCM Service had seven SIAT machines, allowing it to produce around 1,000,000 m2 of printed tape per month. The brand currently has eleven flexographic printing machines, which gives it a production capacity of 1,600,000 m2 of printed tape per month. To keep up with the times and in order to meet customer expectations, TCM Service provides its partners with the MyTCM application to manage their orders.