Manufacturer of printed tapes

The production process at TCM Service respects environmental standards. Only the best raw materials are used in production, guaranteeing high quality and customer satisfaction. The tapes offered by TCM Service maintain their properties in terms of durability, regardless of how much time passes. We offer custom printed tapes on various types of media, with the strong adhesive of the customer’s choice (Hot Melt, Solvent, or acrylic). This tape is a reliable way to protect your shipments from damage. We base our operations on long-term relationships with customers and on carefully managed products. TCM Service is constantly expanding its product range so that every customer finds the option that is right for them.

Flexographic printing

TCM Service offers flexographic printing. This type of printing is very versatile. In most situations, this is a company logo, an advertising slogan, an address details, or a warning message. TCM Service offers printing on PVC, paper, and polypropylene tapes. The ‘sandwich’ method is a great solution. With this method, the printing is done before the adhesive is applied. This ensures that the printing will be resistant to weather conditions and mechanical damage. In addition, prints made using this method are distinguished by their intense colours. Printing can be done in any three colours from the Pantone C and HKS palettes, and sometimes also the RAL colour palette.

Guidelines for preparing prints on adhesive tapes

As a tape manufacturer, TCM Service attaches great importance to the technical specifications of its products, and the quality and precision of the printing. Employees make every effort to ensure that printed tapes are produced to the highest standards and to the specifications of the order. The printing designs for the tape should be prepared according to the requirements (in vector form). All projects that do not meet these requirements (such as images with a pixel structure) must be converted. Without these guidelines both in the logo and in the other graphic elements, the printing die will not be properly prepared and the tape will not be printed. Order processing is much more efficient with files in the correct format.

Providing information for printing on tapes

Tapes are printed using the flexographic printing method. Printing is not possible with pixel-based images, so the data to be printed on the tape should be in vector format. To avoid conflicts between different systems (Windows and Mac), it is worth converting the file to PDF. Importantly, simply saving or exporting to PDF does not solve the issue – paths and fonts must be converted to curves.

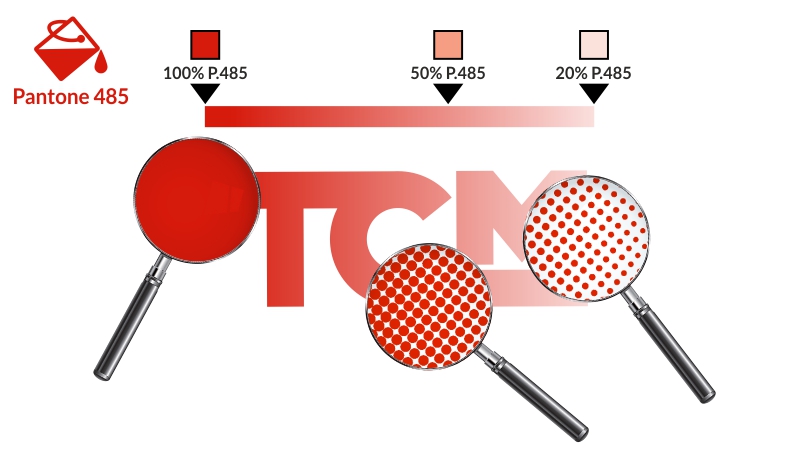

Raster

A raster is a monotone image composed of tiny dots, giving the impression of halftones when viewed from a normal distance. Printing is based on the Pantone C and HKS colour palette, though RAL colours can also be used. Raster allows us to obtain several shades from one colour, while keeping a minimum of 20% and a maximum of 80% of the original Pantone or HKS colour.

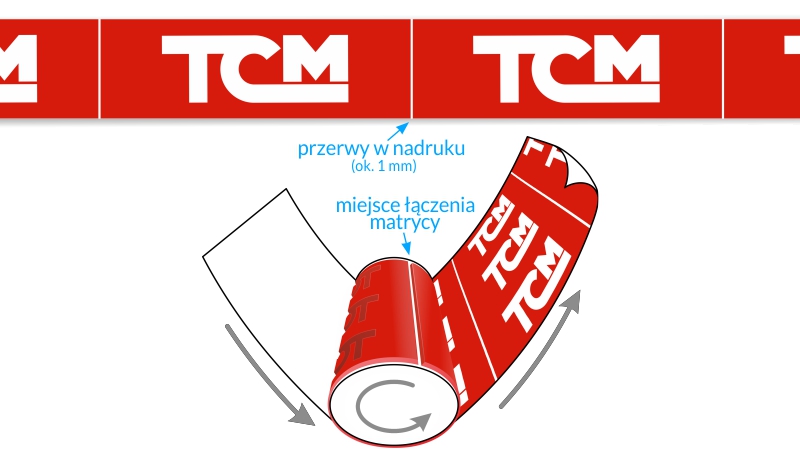

Die length

The length of the dies determines the area that can be used for printing logos and other information as well as the free space between them. TCM Service has dies in lengths of 150.7 mm 188.5 mm, 219.8 mm, 245.0 mm, 251.2 mm, 282.6 mm, 314.0 mm, 345.4 mm, 370.5 mm and 395.6 mm. Printing is done by sticking a die onto a roller, where each rotation of the roller is one repetition of the design on the tape.

Print on the entire surface of the tape

If the customer wants the whole surface of the tape to be printed and the background is darker than the elements on it, a line will be visible on the tape where the dies are joined (1-2 mm). The distance between the lines depends on the length of the die. A special Sleeve die, which only comes in a length of 314.0 mm, can be used such that the lines are not visible.

Edge printing

The base material on which the print is made is usually 144 or 150 mm wide. Most often 3 repetitions are performed with one rotation of the roller. During the printing process or when cutting with a knife, small offsets (1-2 mm) are possible, which are usually not noticeable with a correctly executed pattern.